Mechanical Design Features

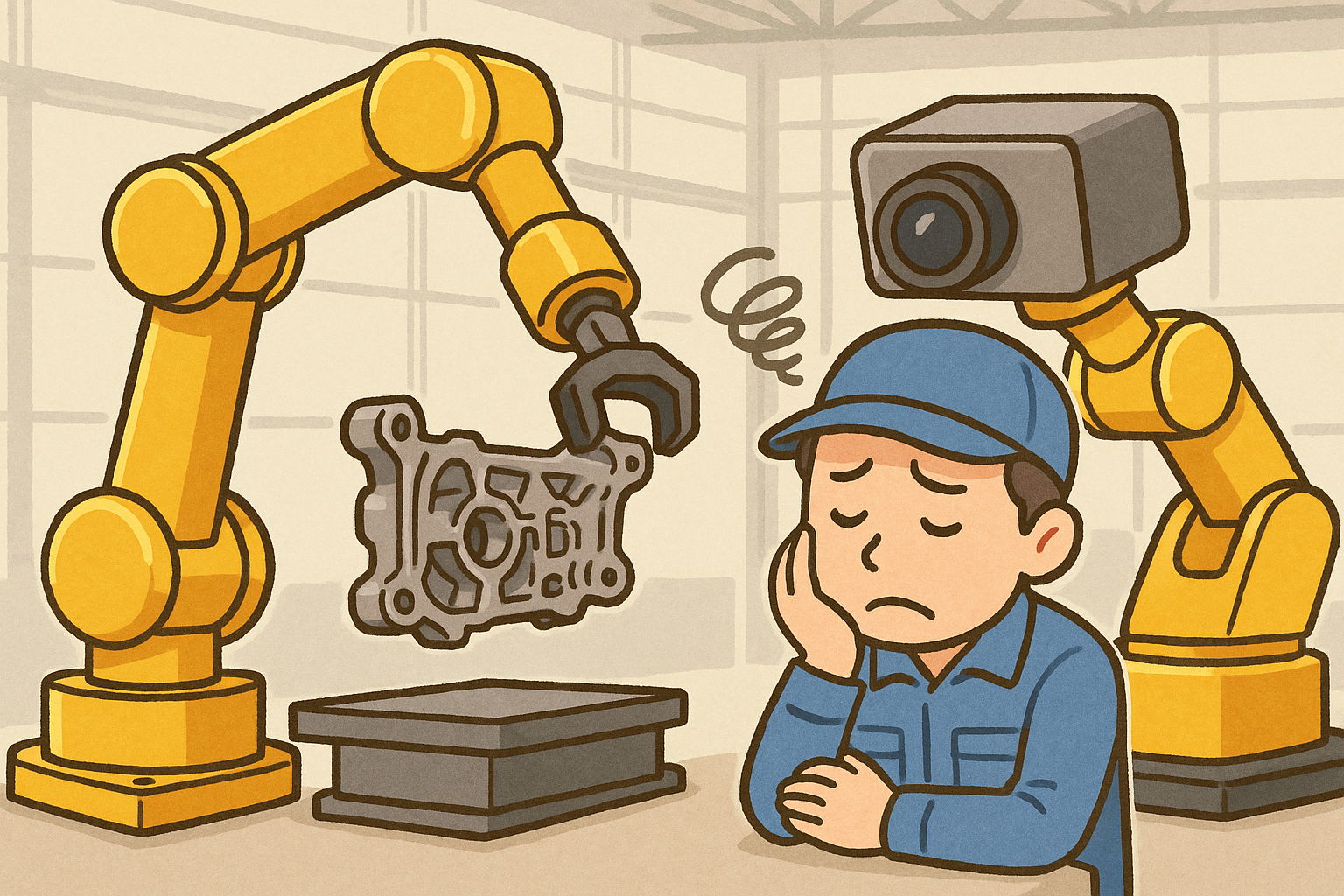

Conventional visual inspection systems for die-cast products often required structures that lifted the product for imaging or large robots equipped with flipping mechanisms to inspect the entire product. To increase inspection speed, some systems operated multiple cameras simultaneously. However, these configurations tended to be complex and large-scale, leading to high initial investment costs. Moreover, most systems were optimized for specific products, making it difficult to adapt flexibly to other items.

To address these challenges, IVI-360™ was developed with versatility as its core concept. The system eliminates the need for a flipping mechanism by combining a six-axis robot arm with a rotary stage, achieving seven degrees of freedom in robot control.

At the heart of the system is a ring-shaped rotary support platform driven by a servo motor. The lower section of the inspection area is open, allowing the product to be rotated and imaged not only from the top and sides but also from underneath using a freely movable camera. Additionally, the camera is equipped with a dual-color (green/red) marker holder that marks the inspected item according to the pass/fail result, reducing the risk of mixing up defective and non-defective products.

Specially designed for aluminum die-cast product inspection, the system optimizes pixel density and imaging conditions to minimize computational load while maintaining sufficient detection accuracy for practical use.

This configuration significantly reduces installation costs while allowing flexible adaptation through simple jig replacement for each product type. Furthermore, users can add or modify inspection conditions for each product, enabling a single system to handle multiple product models.

This technology is patented by The 7th Engineering Co., Ltd. (Japanese Patent No. 7750589 / JPO: P7750589).AI Software Features

Technology for Visualizing the Learning Process

The AI engine built into IVI-360™ does more than simply classify defects on die-cast products — it also provides a graphical representation of what and how the AI has learned.

Traditionally, AI judgment has been evaluated only by metrics such as “accuracy” or “detection rate.” However, for example, the defect type known as “flow mark” can appear as either a shallow, wavy pattern or a deep, distinct groove. If all such variations are simply labeled “NG” (non-conforming) during training, the AI may not fully understand the differences.

IVI-360™ extracts numerical representations of defect features (patterns and textures) from inspection images. This set of data is called the first feature vector. From it, about twenty representative values useful for judgment (the second feature vector) are selected and displayed graphically.

For example:

Flow mark → smooth, wave-like line

Dent → pointed, spike-like line

Stain → irregular, fluctuating line

Because each defect type produces a distinct line pattern, users can visually confirm how the AI “perceives” the defects. By color-coding OK and NG samples, the operator can immediately see which group the current product belongs to. This helps reduce ambiguous judgments and missed minor defects.

When the AI makes a mistake, the graph helps determine whether the issue lies in insufficient feature extraction or inappropriate threshold settings, making retraining and fine-tuning much easier.

This technology aligns with IVI-360™’s concept of using AI not merely as an automatic classifier but as a “partner that thinks together with humans.” It enables field engineers to trust and effectively utilize AI-based inspection with confidence.

This technology is patented by Roxy Co., Ltd. (Japanese Patent No. 7309134 / JPO: P7309134).